Innovative systems for the automotive industry

Thanks to our experience and access to automation we can provide efficient and cost-effective solutions

Powertrain

Cooling water expansion tank

Expansion tanks from Kunststoff Schwanden AG are designed by our engineers to meet all safety-relevant, geometric, and optical requirements for their functionality.

Engine covers

Engine covers made by Kunststoff Schwanden AG using injection molding technology (e.g. MuCell, multi-component injection molding) are designed by our engineers to meet all design, acoustics, airflow, and weight specifications.

Slide and tensioning rails

Our engineers design and select materials for slide and tensioning rails made by Kunststoff Schwanden AG using injection molding technology (e.g. patented multi-component injection moulding, hybrid technology) to reduce coefficients of friction optimally and to meet all functional requirements.

Metal substitutes

Advanced plastics allow our engineers to use the latest calculation methods to design metallic components as injection moulded components.

Metal substitutes

Advanced plastics allow our engineers to use the latest calculation methods to design metallic components as injection moulded components.

Metal substitutes

Advanced plastics allow our engineers to use the latest calculation methods to design metallic components as injection moulded components.

Exterior

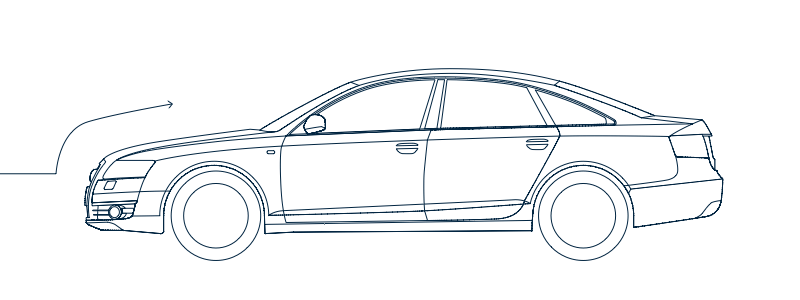

Aerodynamics

Air shutter systems, underfloor components and air ducts made by Kunststoff Schwanden AG using injection molding technology (e.g. MuCell, multi-component injection molding) are designed by our engineers to meet all actuator, OBD capability, kinematic, design, acoustics, and weight specifications.

Rear ventilation flaps

Our engineers have developed the rear ventilation system manufactured by Kunststoff Schwanden AG using injection molding technology (multi-component injection molding in conjunction with innovative assembly technology) to ensure pressure equalisation in vehicle interiors.

Tank filler/plug-in recess systems

Kunststoff Schwanden AG develops tank filler and plug-in recess systems specifically to customer specifications, in compliance with refueling and charging regulations. These prevent liquids and vapors from entering into the vehicle. The locking solution from Kunststoff Schwanden AG prevents unauthorized access to the vehicle's tank filler or electric plug-in system.

Interior

IMD/IML decorative parts

One of the most effective and cost-effective ways to create a decorated part is during the injection molding process.

With the IMD/IML process, an injection-molded part can be decorated directly during the injection molding cycle.

Decorative parts with 3-D look

Kunststoff Schwanden AG uses materials technology to develop high-quality design components using multi-component technology.

Operating elements

Kunststoff Schwanden AG solutions offer the integration of touch sensors and mood lighting.

Release handle and duct for parking brake pedal

Kunststoff Schwanden AG develops interior components and assemblies that meet tight tolerances as agreed, taking into account the instrument panel design specified by the customer. Rubber parts are assembled in a combined, fully automatic robot cell in a single cycle as they emerge from the injection molding machine, with a film applied using a hot stamping process. A fully automatic 100% visual check follows to ensure that the pictogram has been correctly positioned.

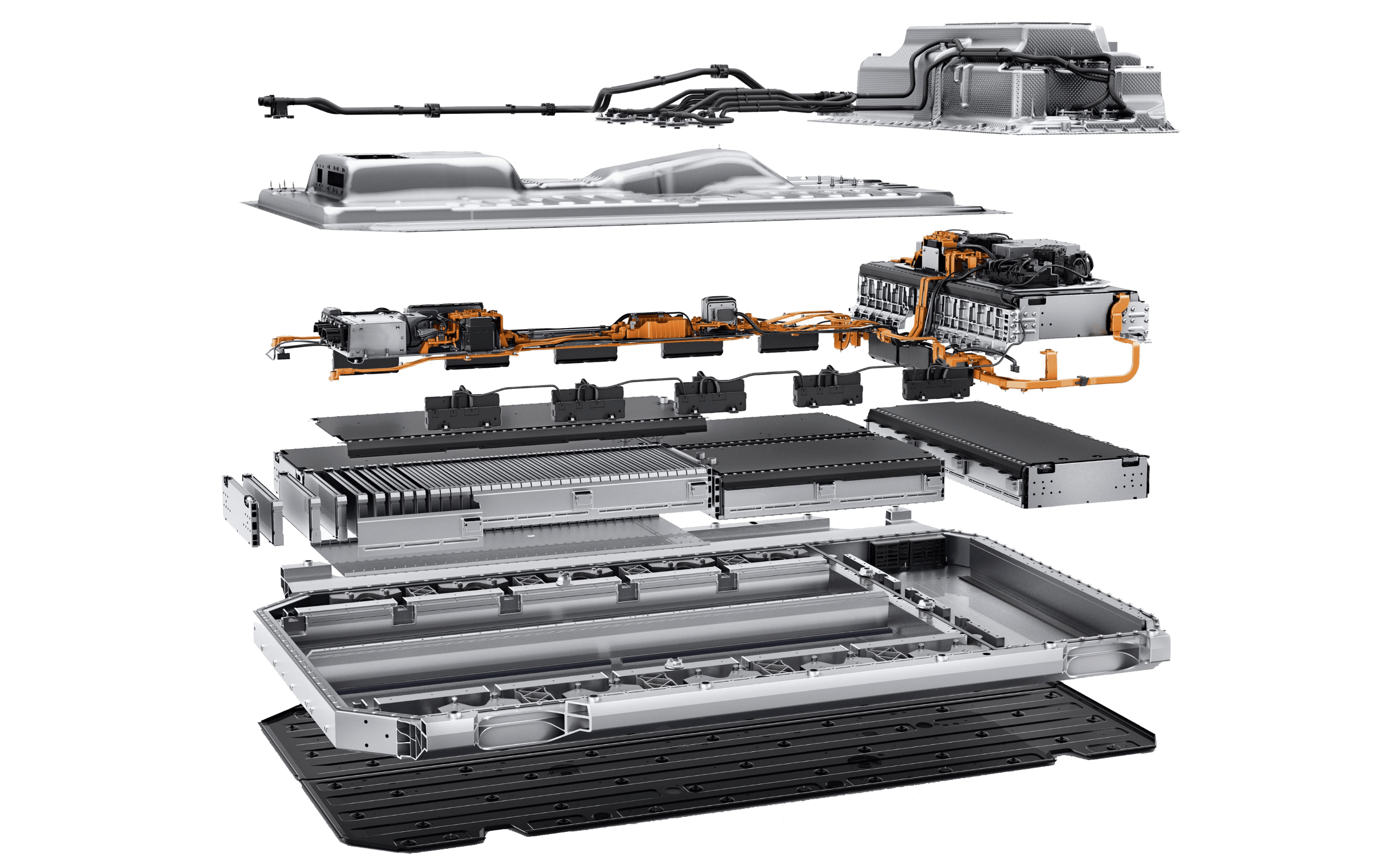

E-Mobility